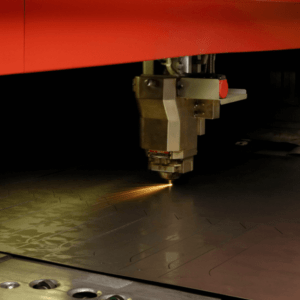

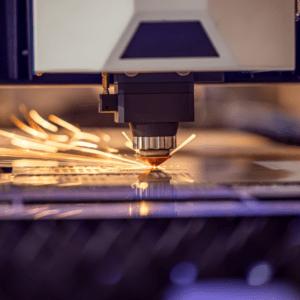

Direct metal laser sintering (DMLS) is a mechanical 3D Printing measure which utilizes a PC controlled, high-power laser shaft to liquefy and combine layers of metallic powder together. DMLS forms completely useful – fast metal models and creation parts in 7 days or less. A scope of metals produces last parts that can be utilized for end-use applications. DMLS materials are for the most part acknowledged to be equivalent or better than those of fashioned materials. DMLS is likewise ideal when the calculation or construction of the part is preposterous in some other cycle (for weight saving plans utilizing honeycomb or latice structures for instance).

We make items for the Industries, for example,

DMLS printing follows the basic process sequence for most of the 3D printing technologies: