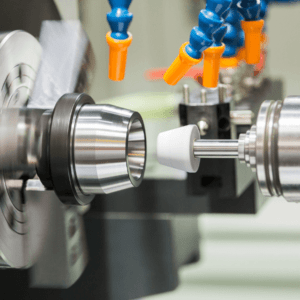

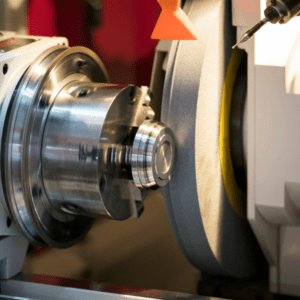

CNC (Computer numerical control) machining is a subtractive assembling innovation. In this, material is taken out from a strong square utilizing an assortment of cutting apparatuses that turn at high velocity (a large number of RPM) to deliver a section dependent on a CAD model. The two metals and plastics can be CNC machined. CNC machined parts have high dimensional exactness and tight resiliences. Computer numerical control is appropriate for both high volume creation and oddball occupations. Indeed, Computer numerical control machining is right now the most savvy method of delivering metal models, even contrasted with 3D printing.

We make items for the Industries, for example,

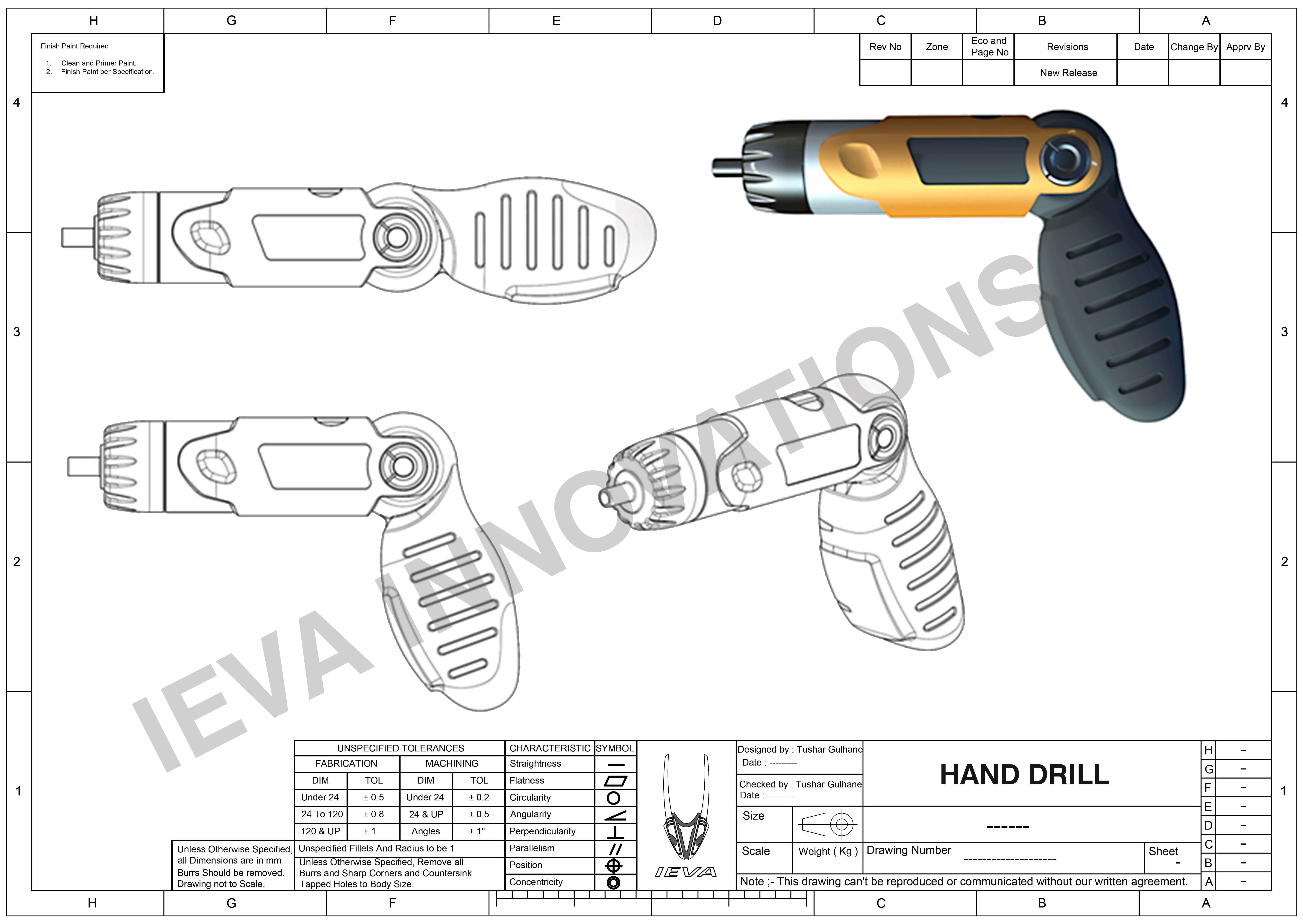

Techniques used to Optimize Design for CNC Machining Parts are as follows –