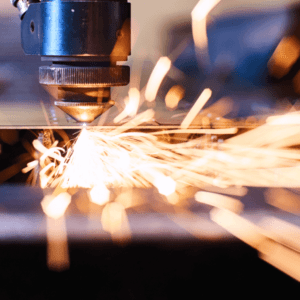

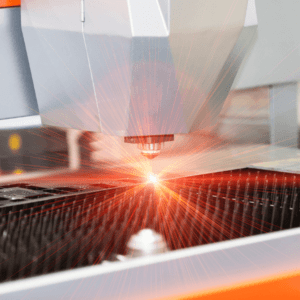

Laser cutting is an innovation that utilizes a laser to cut materials. While commonly utilized for modern assembling applications, it is starting to be utilized by schools, independent companies, and specialists. Laser cutting works by coordinating the yield of a powerful laser most normally through optics. A business laser for cutting materials utilizes a movement control framework to follow a CNC or G-code of the example to be cut onto the material. The engaged laser bar is aimed at the material, which at that point either softens, consumes, disintegrates away, or is passed up a stream of gas, leaving an edge with a top notch surface completion.

We make items for the Industries, for example,

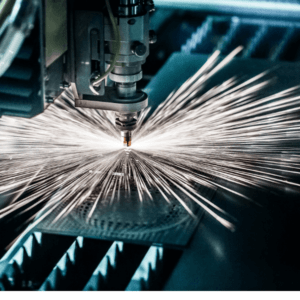

There are many different techniques in cutting using lasers, with different types used to cut different materials.